Car Design News spoke to Magna Exteriors experts Larry Erickson, Global Director of Industrial Design, and Tony Povinelli, Global Product Line Director – Active Aero, about the design possibilities raised by moving aerodynamic surfaces.

Car Design News: The notion of active aerodynamics conjures up images of big wings extending from the decks of supercars. What does active aero mean to a volume supplier like Magna Exteriors?

Tony Povinelli: Supercar aerodynamics are typically designed to create downforce for cornering, whereas we have a very strong focus on drag reduction rather than lift reduction. That’s what gives OEMs the ability to provide what their customers are looking for while also allowing them to meet their efficiency requirements.

When you look at all the emissions regulations out to 2025, and the need for improved fuel economy, active aero is definitely the next step in how auto makers are going to meet those regulations. There’s been a history of powertrain improvement that continues, styling is still key and critical in reducing drag coefficients, and lightweighting has been in play for quite a while now.

Improving aerodynamics is the next piece that OEMs are going after, and we’re clearly seeing that growth already.

Active flaps open

CDN: Active grille shutters, which cut drag when full cooling isn’t needed, are now quite widely adopted. What is the next frontier for active aero?

Povinelli: This year we’ll make three million active grille shutters and progress in aerodynamic products continues to grow. We’re developing an entire suite of products that will arrive in phases.

In January, the 2019 Dodge Ram pickup truck launched with an active front deflector, which extends below the bumper at speed. It’s the first in its segment and the first high-volume active front deflector in the world.

Next, we’ll see concepts like active underbody panels, active rear diffusers and active wheel deflectors. The underbody is a big play. There’s a whole host of possibilities that we continue to investigate, so when a customer comes to us we have a solution ready for them.

CDN: To what extent might the ability to alter the shape of a vehicle at speed unlock new design possibilities?

Larry Erickson: There have been a few show cars that have taken exterior panels and moved them. Often those panels are behind the rear wheel, at the end of the body, because that’s where you can dramatically affect the flow separation off the vehicle. You’ve also got potential at the roof and backlight of the car.

2015 Mercedes IAA Concept had an extending tail to cut drag

As we move to electric and hybrid cars, we’ll see a very clean underbody – I think the Tesla Model X is a good example. As those drive systems come in and the underbody gets cleaned up, all of a sudden, things behind the rear axle could become much more important, so rear fascias could be affected. It’s going to be an interesting time. I don’t think we’ve seen the end of what surfaces will be involved with active aerodynamics.

Povinelli: There will be new flexibility in design – to sculpt the vehicle overall to create something more pleasing and then take active aerodynamics to still achieve the performance or drag reduction we need. So aerodynamics won’t dictate design.

It’s like the lift devices used to raise the front end of Lamborghinis and Ferraris. The lift feature enables those cars to run at an extremely low ground clearance, which improves high-speed aerodynamics, and when necessary raises the front end in order to survive day-to-day ramp angles and speed bumps.

In some cases, active aero will have direct marketing value as well – like jewellery you can hang on the vehicle. We have created A-surface active aero products, like the visible active grille shutter we launched in the middle of 2016 for the Mercedes E-Class. It’s very similar to a regular grille but it has vanes that open and close, which are visible to the customer.

2016 Mercedes-Benz E-Class’s active grille shutters

CDN: Will active aero devices always be rigid items, or might we see flexible, morphing surfaces in the future?

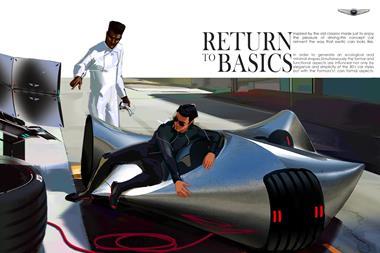

Povinelli: We’re still at the early stages and I do see shape-shifting parts as something coming in the future, to really optimise the benefit overall. When you look at what students create – a lot of times they pull things from nature, things that move or adapt to airflow. Those ideas are definitely important in design and being considered for the future.

CDN: Do designers need to consider active elements right at the start of the design process? Or can movement be added to clean up airflow much later in the day?

Povinelli: Aerodynamic efficiency has such an impact on the vehicle overall, it really affects the styling. Getting in very early to the studio, to drive the most optimized design, is really what we’re striving for.

Erickson: Active aero can be effective as an early development consideration or as a late addition to achieve program targets. It is always better to have all vehicle content defined early in the development process, but often that is not possible. By working early in the vehicle development process with Tony’s group, a vehicle team has a significantly greater opportunity to identify design factors that impact the potential effectiveness of active aero systems.

CDN: There is often a design tension between efficient shapes and emotional shapes. Will active elements be able to bridge the gap?

2019 Dodge Ram’s active front deflector

Povinelli: That’s exactly what we’ve done for the Ram pickup. The styling is very aggressive, with a very abrupt front end, but by implementing our active grille shutter and active front deflector they’ve gained a significant drag reduction on the vehicle.

Because those trucks sell in big numbers, the active front deflector alone is going to save 10 million gallons of fuel per year. That’s pretty important in the big picture, and pretty impactful as well. And that’s one device; it just shows the value of what these aerodynamic devices can do.

Erickson: At Magna, the parts we make are usually high volume. A lot of active aero started out as very niche – if you look at downforce devices it’s a supercar market of a few hundred cars a year. What we’re doing with the Ram is extremely high volume, and you need to have manufacturing expertise to bring that kind of product to work in an everyday environment, not just at Pebble Beach.