Car Design News spoke to Larry Erickson, Global Director of Industrial Design at Magna Exteriors, about the changing nature of design education and how students can get the best from internships and design competitions.

CDN: Magna Exteriors is a major Tier 1 supplier with its own in-house design team. What motivates its involvement in student design competitions like CDN’s Car Design Awards China?

Larry Erickson: When Grahame Burrow [Global President of Magna Exteriors] kicked off the initiative to get Magna Exteriors more aligned with the design community, one of the first things that evolved was the Magna Bold Perspective Award at LTU. That was like a pilot for the way we’d like to continue to work. I think it opened up a lot of people’s eyes, to look at things in a different way.

Working with students is definitely a two-way process. Partly that’s because for students to be successful and for Magna Exteriors to be successful, we both need to get out in front of automotive design developments.

When I look at student proposals for the CDN competition, most of them involve innovation, whether it’s materials, or mechanical, or interaction design. That’s always been a fundamental part of the design education process, whether it’s at LTU, RCA, Pforzheim, ArtCenter or CCS. You look out into the environment and you try to anticipate what’s coming.

Students are sometimes a little more optimistic than reality, but that’s natural. For Magna to be successful, we’ve got to be looking down the road too. By having this dialogue with students, by bringing them in on internships, by working with them on projects, I think we get a better skill-set at listening. We also gain a broader range of influences that ultimately benefits our customers.

CDN: What kind of things do you look for in students’ entries?

Students tend to generate designs with features and shapes that challenge conventional methods of making automobiles. They’ll push physics to an unbelievable level, whether it’s shape, draw depth, form retention of surfaces or packaging of components. Today’s design solutions seldom restrict their imagination. You often see ideas that you would literally have to print.

Even though a student design may not be feasible with present constraints, they often capture the wants and needs for something automobile manufactures will be working on next. They’ll also see innovation with consumer products and think, “I could do that in a car.” They just grab those things like a sponge. We need to look harder at these ideas because they may contain tomorrow’s challenges

CDN: What sort of relationships does Magna Exteriors have with automotive design schools?

With some we have a very direct relationship, partially because of location but also because it’s a small group of schools, and we know the people involved. Automotive design schools have always had very close ties to the industry. OEMs have a long history of supplying teachers, giving guidance on curriculum, defining necessary skill sets and providing financial support.

At Magna Exteriors, our design team is in some respects a subset of the larger automotive design industry. We use our collective knowledge to support the automotive design industry, not only our customers but also the development of students who will potentially play important roles in the next generation of vehicles.

A developing area for our industry right now is increasing use of animation. At Magna we are finding greater applications for it because it not only lets you envision products more effectively but it also helps with marketing and collaboration with customers. Putting an innovative design in context with a compelling story traces back to the earliest days of automotive design, and animation takes that process to a higher level.

I wouldn’t be surprised, in a few years’ time, to see animation become a key part of the CDN design competition.

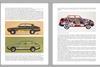

Lawrence Technological University design students Fadi Hannawa and Jacob Lovins worked with Magna Exteriors to envision future mobility

CDN: What does Magna Exteriors offer in terms of placements and work experience?

So far we’ve been focused on summer internships – we’re evaluating portfolios right now – but a lot of schools have opportunities year-round, so we’re looking at different possibilities. I think our program will grow to the extent that it’s manageable and beneficial for both sides.

Interns work right in the studio and we try to manage things so they can add their work to their portfolio. I know some companies have interns do work they can’t show, but we believe students benefit most if they can share their work with other people. We had three students last summer and cleared everything for them to use, so it worked out well.

CDN: What kind of projects might an intern work on at Magna Exteriors?

One of our interns, Henry Zhu, did a demonstration project around aerodynamics for Class 8 vehicles, or heavy trucks. That was a very big job and he produced great work that we used publicly. It involved making a surrogate vehicle to show a product in situ. Instead of having some static part in space we could demonstrate how an active aerodynamic device deploys and what it looks like on the road. A big part of our world is not just making things, but making the connection to our customer.

Magna Exteriors provides components and systems for a very broad range of OEMs. This diversity creates projects in all vehicle segments – some near-term and very specific, others more futuristic and wider in scope. No matter the project, we have always enjoyed the participation and unique perspective that interns bring.

A commercial heavy truck designed by Magna Exteriors design intern Henry Zhu demonstrates the use of active aerodynamic features

CDN: What advice would you give to students to improve their future prospects?

One of the things we look for is the ability to put a complete vehicle together in multiple views. If you can really show that you can move something around in space and work to develop it, that’s a high water mark. When you open a portfolio and see not just one compelling sketch but four or five views, that person shows the ability to work at a professional level. I know they can finish the job I need finished.

The ability to tell the story behind a design is also compelling. A lot can do it verbally, but if you can do it graphically, that’s huge. It’s not just about shape, but a shape and the story that goes with it.

Emotion is where the profit is. Even Class 8 truck buyers know that. They’ve got to hit their metrics, but if you can do that with something that looks compelling, they know they’ll have happier employees. A driver can look up at their truck and think, ‘That’s my office, I like it.’

Magna ID’s recipe for a killer portfolio:

- Your projects must define design problems as well as visual solutions, creating a relevant and innovative aesthetic that links the vehicle attributes with both brand and customer.

- Concepts can address emotional as well as functional needs, but evidence should be included that links initial research to your final concept.

- Demonstrate that you can refine and complete a design solution. Don’t simply put forward one compelling image plus preliminary proposals. Show how your design works in all views and that it remains compelling as you add detail and constraints.

- Spend time developing the most effective way to present your design solutions. Images, format, colour and graphic elements all drive understanding of who your project is aimed at and why your solution fits the problem.

- Provide evidence of collaboration. Successful designers work with many stakeholders, so demonstrate your ability to empathise with the customer’s problem and work with others to define a solution.